Case I: environmentally friendly oil and gas fields with no solid weighting agent HWJZ-1

HWJZ-1 is an environmentally friendly high-density non-solid weighting agents, and organic salts (NaCOOH, KCOOH, CsCOOH, etc.) increase the fluid compared with conventional inorganic salt (NaCl, KCl, CaCl2, MgCl2, etc.), with a higher density corrosion smaller, anti-temperature stability of higher compressive strengths, while environmentally friendly, affordable, formulated density up to 1.82g / cm3.

TT12-1-2 well is an appraisal well in the East China Sea, the pressure coefficient of about 1.55, are abnormally high pressure gas reservoir. By geological design, in September 2013 to mid-course test reservoir. Gas well control in accordance with the requirements of the test fluid density required to achieve 1.70g / cm3 or more, the conventional solid-free test solution can not meet the requirements of the well. To this end, the company developed a high-density non-solid phase weighting agent HWJZ-1, the preparation of an organic salt test liquid density of 1.72 g / cm3. The liquid used to test the middle packer seat seal protection solution, effectively preventing the heavy mud buried precipitation card packer accident, to ensure the smooth operation of the test.

Case II: Oil-based drilling fluids HW OBS Applications

HW OBS oil-based drilling fluid system developed by an independent company, formed Chaiyou Ji, Bai Youji two systems (density: 0.9 g / cm3 ~ 2.85g / cm3, resistance to temperature: 80 ~ 180 ℃) and matching " oil-based drilling fluids technical Manual ", rheology, electrically adjustable stability, low fluid loss, resistant to water, soil, salt, water-based drilling mud and water pollution performance, better environmental protection, site preparation process is simple easy maintenance. HW OBS system has been in Xinjiang, Sichuan and other areas used to good effect.

X505 is the western Sichuan a deep horizontal wells, the presence of high formation pressure, wellbore instability, large friction and other technical problems. Conventional water-based drilling fluid, the accident rate, low efficiency of drilling, borehole poor quality; high cost of imported oil-based drilling fluids. The HW OBS wells using oil-based drilling fluid density 2.10 ~ 2.15 g / cm3, made wellbore stability, a significant reduction in friction, greatly improve the speed of drilling, logging, cementing casing running a successful, construction safety, smooth, efficient, excellent results and a record five horizontal wells in the same area the same type of economic and technical indicators:

① Φ215.9mm longest horizontal section of the wellbore to reach 907m;

② horizontal section ROP fastest to reach 4.88m / h; horizontal section shortest construction period, reaching 22.92d;

③ level segment longest single drill footage, reach 903m;

④ horizontal section daily footage highest, reaching 117m.

X505 Well, HW OBS system performance indicators have reached the imported oil-based drilling fluids, praise and work party contractors.

H101 is well northern appraisal well, drilling depth of 3250 meters. The well was drilled in Anjihaihe quality cream containing high water sensitivity greenish gray mudstone, expansion and dispersion necking serious collapse; dip greater than 50 °, pore pressure and collapse pressure ultra high; water-based drilling fluid density of more than 2.50 g / cm3, and even as high as 2.65g / cm3. The previous drilling accident rate, long drilling cycle, high cost, low success rate. To this end, three open wells using HW OBS ultra-high density of oil-based drilling fluid density of 2.38 g / cm3 ~ 2.46g / cm3, electrical stability has been higher than 2000V, high temperature and high pressure loss control in less than 3ml, logging , casing, cementing a smooth, successful, solve the region has been plagued by high pressure, high water-sensitive shales drilling technical problems, while hitting a remarkable technical indicators:

① Anjihaihe hole section in the region the highest average ROP (11.65m / h), up to date footage (240m), the shortest drilling cycle (6.9d), a trip to the highest drilling drilled;

② Chong average Anjihaihe well hole section enlargement rate the lowest (average hole enlargement rate of about 3%);

③ oil based drilling fluid having a density (2.46g / cm3) Chong drilling contractor record.

Case 3: organic friction modifiers GXJM-1 Applications

In 2008, Southwest Branch developed organic friction modifiers GXJM-1, the agent adsorbed film formed on the surface of the steel has a higher carrying capacity, can still play at a high isolation between the drill string and casing pressure that is effectiveness and reduce friction. When a large inclination or dogleg large drill wells will not dry grinding sleeve occurs, can still play a role in lubricating antifriction. It cooperates with the tool joint wear, western Sichuan and northeastern Sichuan for deep well, ultra-deep drilling, a better solution to the drilling process casing wear and early breakage problems.

In April 2008, DY4 wells drilled to a depth of about 5500m, during drilling debris found in fish have more iron, iron filamentous form was short, thin sheet, analysts believe is set φ177.8mm tube produced by wear. In order to slow down the casing wear, from the depth of 5636 m in the drilling fluid start adding 1.43% of organic friction modifiers GXJM-1, casing wear loss was reduced 45.9%, showing good friction reducing effect.

In June 2008, Xll four open wells in 4750 ~ 5291 m well section, adding 0.5% to 1% of organic friction modifiers GXJM-1 to continue drilling in the drilling fluid, the entire drilling process quarto smooth wellbore flow, mud pump replacement parts significantly reduced the number. The well was drilled deep 5291m, drilling, logging, casing, cementing operations smoothly.

Case Four: high temperature drilling fluid with salt fluid loss JHJS-200 Applications

Drilling fluid loss agent with high-temperature salt JHJS-200 is a colorless or pale yellow viscous liquid, is a cationic monomer, heat stabilizers, initiator, etc. synthetic fluid loss.

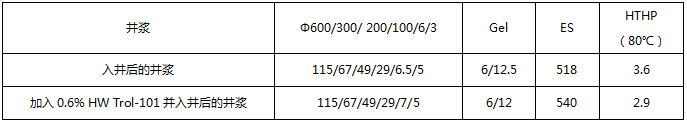

February 14, 2012 to 16, in ZG105H well used JHJS-200, using the Lower Ordovician strata Yingshan, limestone, depth of 6615 meters, the drilling fluid system of polysulfide system. Indoor experimental data shown in Table 1.

Table 1 Adding laboratory test data of JS-200

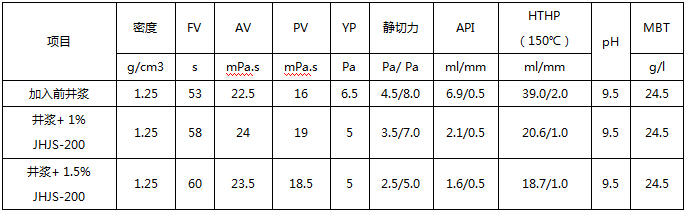

In accordance with the cycles is added directly to the slurry well JHJS-200, before and after the treatment agent is added to the drilling fluid properties as shown in Table 2.

Table 2 on-site wells slurry was added JHS-200 measured data before and after

Field application shows, JHJS-200 can significantly improve the original drilling fluid pressure, high temperature and high pressure loss performance and can meet the requirements of high temperature and pressure deep drilling, and the product is no fluorescence, no effect on the electrical measurement.

Case 5: drilling oil-based mud resistance to high temperature fluid loss additive HW Trol-101 Applications

Oil-based mud drilling fluid loss additive HW Trol-101 is a high temperature synthetic polymers. There are good in oil dispersion of oil-based drilling fluid rheology without adverse effects, with a variety of oil-based drilling fluid system other processing good compatibility, with good resistance to high temperature fluid loss results.

Chongqing shale gas development using an oil-based drilling fluid, the original use of fluid loss additive effect is not obvious. March 2015, Party JY46-3HF well replace the original fluid loss additive, after adding HW Trol-101 well in the slurry, reduce water loss, breaking the voltage increases, the viscosity unchanged (see Table 1 Test Data ). Compared with the original fluid loss agent, HW Trol fluid loss effect is obvious, lower prices, has been applied in the region.

Table 1 fluid loss agent site usage data